Pictures Of Bridgeport Vertical Mill

Vertical Mill Picture Hospetsteels. Vertical roller vertical roller mill is a type of to grind materials into extremely fine powder for use in mineral paints pyrotechnics cements and.

WhatsApp)

WhatsApp)

Vertical Mill Picture Hospetsteels. Vertical roller vertical roller mill is a type of to grind materials into extremely fine powder for use in mineral paints pyrotechnics cements and.

Cement is a fine powder, obtained from the calcination at 1,450°C of a mix of limestone, clay, and iron ore. The product of the calcination process is clinker—the main ingredient of cement—that is finely ground with gypsum and other chemical additives to produce cement.

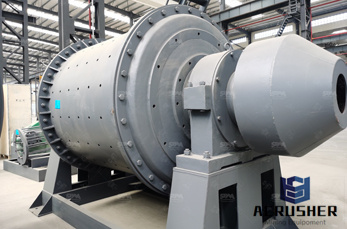

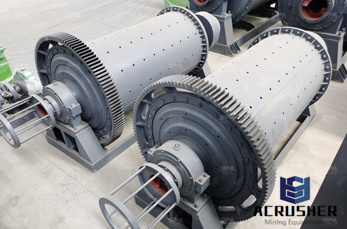

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum .

Cement mill Wikipedia, the free encyclopedia A cement mill (or finish mill in North American usage) is the equipment used to grind the ... Most cement is currently ground in ball mills and also vertical roller mills .... A more comprehensive picture of fineness is given by particle size analysis, ...

• HardiePanel® vertical siding can be installed over braced wood or steel studs spaced a maximum of 2 ft. (610mm) Irregularities in framing and sheathing can mirror through the finished application. • Consult ESR1844 for fastener schedule as well as additional technical information at

Vertical Roller Mill in Cement Industry. From: Date: 09:26. As we all know that the vertical roller mill is one of very important powder making machines in the cement industry. Because of the high efficient and high capacity the vertical roller mill, so use the vertical roller mill to process the cement raw powder is the most ...

Photos Of Vertical Cement Mill Grinding Plant | Manganese Crusher. Search photos of vertical cement mill grinding plant to find your need. Mining and Construction Machinery is a global manufacturer and supplier, We supply full .

Loesche Hansaallee 243, 40549 Düsseldorf, Germany Rated based on 296 Reviews "Dancing together. The last new type cement mill also...

Vertical roller mill Wikipedia, the free encyclopedia. Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, .

energy of a cement plant. Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press. This and further arguments led to the increased share of VRM for the grinding of finished cement. Taking into account that

today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill

Vertical cement mill,Vertical roller mill for cement industry,for sale,price In cement plant, Vertical Grinding Mill is very important since most of the raw materials will have to be crushed before being used to process cement, such as ...

2. Equipment problems and cause analysis As an important part of equipment in modern cement production system, Vertical Mill has expensive spare parts and long supply period. Once damaged, it will have the following impact on production:In the face of longterm shutdown, direct economic loss is huge;When the abrasion of the grinding roll and the lining plate of the grinding disc is excessive ...

May 24, 2018· Construction[ 3366 Ratings ]Related Postsdifference between vertical raw mill and difference between vertical and horizontal cement mill difference between vertical and .

Aug 30, 2012· This saves the extra fuel cost and makes cement somehow economical. Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant. There are also various other raw materials used for cement manufacturing. For example shale, fly ash, mill scale and bauxite.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

Cement ball mill and vertical cement mill grinding vertical roller mills versus ball industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is.

Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal slag. It has the features of simple structure, low cost of manufacture and use. Vertical roller mill has many different forms, but it works basically the same.

About HardiePanel ® Vertical Siding. Combine with HardieTrim® boards for a rustic boardandbatten look. Or, go for the more minimalist look of simple vertical lines. USE IT FOR: Works well with farmhousestyle or modern homes.

Residing your house with HardiePanel vertical siding—or combining it with HardiePlank® lap siding—is sure to add visual punch to your design. ... Fiber Cement Siding Maintenance . ... Browse the photos below to see James Hardie products on real Hardie homes.

Greater Detail: Cement Plant Operations Handbook Crewmen''s Guide, Finish Mill Systems Cement mill A 10 MW cement mill, output 270 tonnes per hour A cement mill (or finish mill in North American usage[1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement..

Suction type mills are designated as XRS whereas pressurized mills as XRP and HP. The nomenclature of each letter is as follows: X Frequency of power supply (50 cycles /sec) R Raymond, the inventor of bowl mills. S Suction type with exhauster coming after the mill P Pressurized type, with primary air fan coming before the mill

Cement Vertical Roller Mill . Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc. Application : Cement Plant, Cl

CEMENT SikaGrind® FOR VERTICAL ROLLER MILLS CEMENT 4 SikaGrind® FOR VERTICAL ROLLER MILLS 5 Pilot Mill (Picture: Loesche , Germany) The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid: ́ Increased production rate, energy saving

WhatsApp)

WhatsApp)